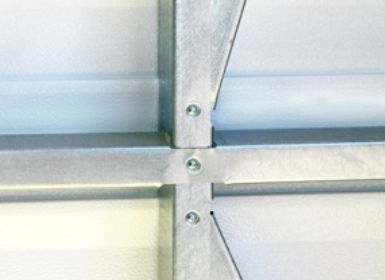

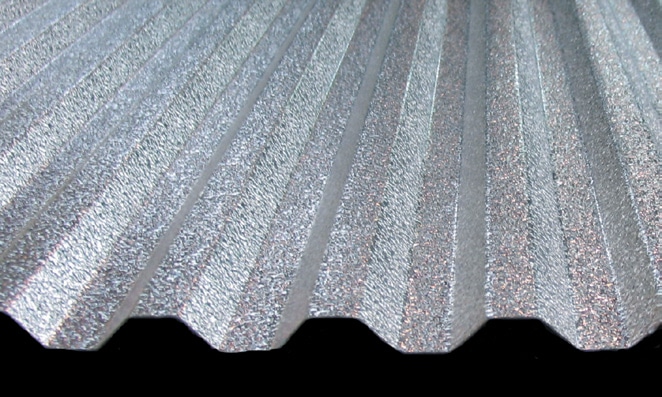

Built with 18-gauge G-90 galvanized steel for long-lasting performance.

Greenhouses for Sale in Gainesville, Florida

Customizable & Durable Greenhouses for Your Growing Needs in Gainesville, FL

Whether you’re a seasoned horticulturist or a passionate home grower in Gainesville, Nelson’s greenhouses are designed to provide the perfect environment for plant growth. Our high-quality Accu-Steel greenhouses are built with durability, efficiency, and customization in mind—ensuring optimal plant health and maximum productivity for any growing setup.

Contact Us to Customize Your Greenhouse

The competitive cost and pleasing appearance of this greenhouse will make it a welcome addition to your backyard or commercial nursery.

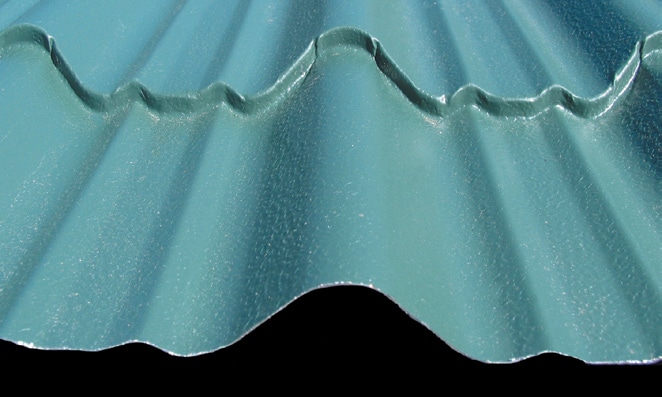

All walls and roof frames as well as the floor structure are manufactured using 18 gauge G-90 galvanized steel. On our Greenhouse floor structure, it comes standard without a floor, but we offer as an option a plastic composite floor that will give many years of maintenance free use. The exterior of the greenhouse is covered with professional grade fiberglass or poly-carbonate panels manufactured specifically for greenhouse use and performance. The Lark Accu-Steel Greenhouse is designed to give the quickest and most efficient growth to your plants and to promote fast rooting of cuttings and efficient germination of your seed beds.

Our greenhouses can be built and configured with an assortment of options to meet virtually any growing need you may have. When you consider the purchase of a greenhouse, critically evaluate the competition, compare them all to Lark, and we are sure you will completely understand what we mean when we say “why not the best?

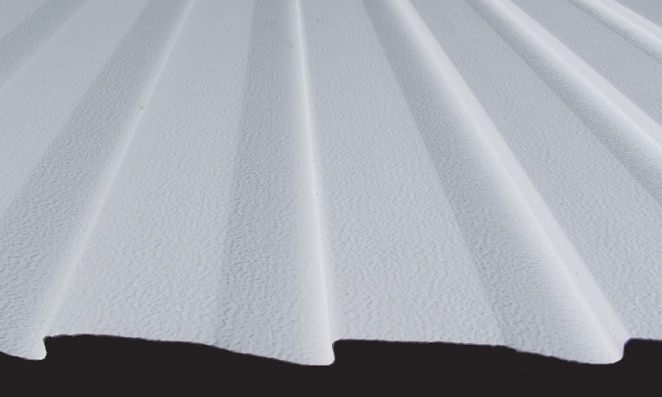

White

Cream

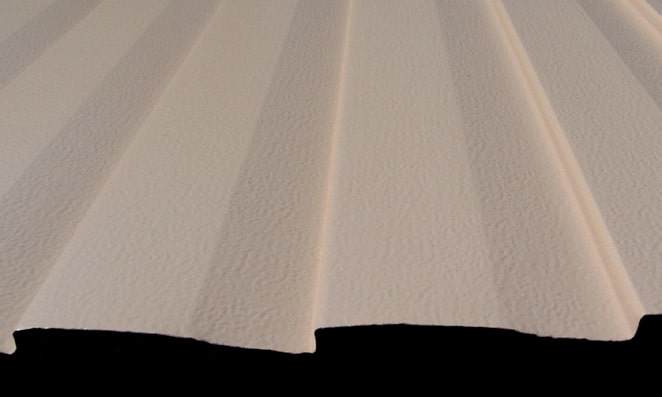

Antique Beige

Burgundy

Pewter

Black

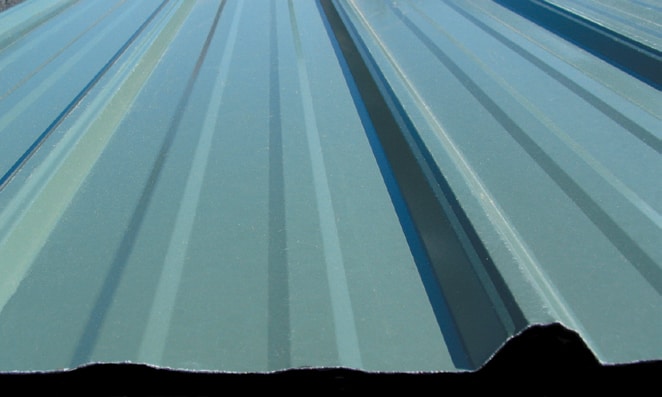

Blue

Clay

Green

Brown

Barn Red

Sage

Dove

Candy Apple Red

Cedar Brown

Red Wood

Accu-Steel Frame Buildings

The Lark Accu-Steel frame building is the biggest advancement in portable building design and construction in the last 40 years. We manufacture the Accu-Steel using one of the most precise and advanced rollforming systems available. The strength, quality, and durability of this steel frame system are truly awesome. The Accu-Steel is manufactured using a totally new concept of rollforming and assembly. A system and method of steel stud construction that is unprecedented.

Accu-steel Truss Roof Section

Accu-steel Diagonal Door Support

Accu-steel Wall Connection

Accu-Steel Corner Bracing

Accu-Steel Rigid Roof Frame Sections

Accu-Steel Roof Connection to Side and End Wall

For years, steel stud construction has utilized a system of U-channels for the top and bottom plates and C-channels for the studs. When using this system, the U-channels and studs have to be measured and marked for center placement. This system lends itself to mistakes in measuring and stud placement. Using this archaic method of fabrication and assembly compromises the accuracy and quality of the finished product.

We manufactured the Accu-Steel building using a state of the art computerized rollformer and software system. This system utilizes C-channels for all structural components, the top and bottom plates as well as the wall studs. This amazing system measures and notches the C-channel for precise stud location. It dimples and punches the C-channels and studs for perfect fastener location and alignment. The building structure created by this rollforming system looks like it was made by a metal working craftsman. Everything on this building system fits and finishes like you expect.

The frame of the Accu-Steel is rollformed from heavy duty 18 gauge G-90 galvanized material that not only give you superior strength and durability, but also provides needed rust protection.

If you are interested in a portable building, you owe it to yourself to critically evaluate this new high tech building system. See why we are sure you will agree that strength, quality, and value like this does not come along every day.

Great Reasons to Buy an Accu-Steel Building

- Steel does not warp, split, crack or creak;

- Steel has the highest strength to weight ratio of any building material;

- Steel is not vulnerable to termites or any type of organism;

- Steel does not burn or add fuel to the spread of fire;

- Steel has less probability of damage in high winds, stronger connections (screwed vs. nailed);

- Steel is dimensionally stable; it does not expand or contract with moisture content.

- Steel produces less scrap and waste (2% for steel vs. 20% for wood);

- Steel is environmentally friendly — 100% recyclable, saving landfill space.

Roof & Siding Metal Profiles

Aluminum Dutch Lap Siding Panel

Steel Dutch Lap Siding Panel

Steel Sturdi-Rib Roofing Panel

Aluminum Twin Rib Roofing Panel

Aluminum Box Rib Roofing Panel

Aluminum Permatile Roofing Panel

Floors

Floor 23/32″ T and G Plywood Installed

Plywood Installation

One of the most outstanding features of our Lark floor system is the way we connect our 23/32″ treated plywood to our floor cross members.

We don’t use nails that can back out and weaken the floor. We use only plated deck screws that give the floor more strength and rigidity than nails. When we place this 23/32″ panel on 16” centers we are able to give you a floor loading of 125 P.S.F. The reason we use this floor loading is to insure that the super structure of the building is adequately supported and that the integrity and stability of the Unit is not compromised.

Doors

- 46”x72” Insulated Door

- 60”x72” Insulated Door

- Insulated Double Door

- 6×7 Garage Door

- 8×7 Garage Door

- 9×7 Garage Door

- 9 light window in door upgrade

Windows

- Small

- Large

- Extra Large

- 12”x12” Vent

Electric

- Standard Receptacles

- Standard Lights

- Fluorescent Lights

- 220 Hookup

- Recessed Wiring Upgrade

Shelving (charged per linear foot)

- 12” Deep

- 18” Deep

- 24” Deep

- 36” Deep

- 48” Deep

Why Choose Nelson’s Greenhouses in Gainesville?

Durable steel construction

Superior growth conditions

Customizable designs

Low-maintenance flooring

Proven performance

12 Ways to Use a Greenhouse in Gainesville, FL

Nelson’s greenhouses offer versatile uses beyond just growing plants! Here are 12 ways customers in Gainesville can use their greenhouse:

- Year-round gardening – Protect plants from extreme weather, allowing continuous vegetable and herb growth.

- Seed starting & propagation – Provides a controlled environment for seed germination and cutting propagation.

- Specialty crop growing – Ideal for exotic plants, tropical fruits, and medicinal herbs that require stable conditions.

- Organic farming – Enables pesticide-free and chemical-free organic produce cultivation.

- Hydroponic & aquaponic systems – Supports soil-free growing techniques for higher yields in a smaller space.

- Flower cultivation & arrangements – Perfect for growing flowers for personal use or floral business production.

- Encourage pollination near your greenhouse – Plant flowers and shrubs around your greenhouse to attract butterflies and bees, supporting natural pollination without enclosing them inside the greenhouse.

- Herb & spice drying area – A controlled space for air-drying herbs like basil, oregano, and lavender.

- Mushroom farming – Greenhouses provide the humidity control needed for cultivating gourmet mushrooms.

- Houseplant & succulent sanctuary – A protected space with natural light and ventilation to help houseplants and succulents thrive year-round.

- School or community garden – Educational STEM projects and community food-growing initiatives thrive in a greenhouse.

- Winter storage for sensitive plants – Protects sensitive or tropical plants during harsh winter months.

Benefits of owning a greenhouse for your Gainesville, FL home

Investing in a greenhouse offers more than just a place to grow plants—it creates a functional and enjoyable space that enhances your home and lifestyle.

Year-round gardening

Homegrown, organic food

Beautiful backyard feature

Saves money in the long run

Protects plants & expands growing options

Customizable to your needs

Create Your Own Backyard Nursery in Gainesville With a Nelson’s Greenhouse

Transform your greenhouse into a thriving nursery where you can grow, nurture, and care for plants with ease. Whether you’re starting seedlings, propagating cuttings, or managing a collection of flowers, a Nelson’s greenhouse provides the ideal controlled environment for your plants to flourish.

Greenhouses are perfect for plant enthusiasts & home gardeners in Gainesville. A backyard nursery greenhouse gives you the freedom to experiment with different plant species, grow in bulk, and enjoy gardening in a dedicated space. With customizable ventilation, shelving, and lighting options, Nelson’s greenhouses are designed to help your nursery thrive! Why use a greenhouse for a nursery?

Protect young plants

Optimize growth conditions

Grow a variety of plants

Expand your gardening space

Start your own plant business

Custom & Turnkey Greenhouses in Gainesville, Florida – Designed for Your Needs

At Nelson’s Buildings, we offer custom and turnkey greenhouses to fit your unique gardening needs. Whether you want a fully equipped greenhouse ready to use or prefer a custom design, our structures are built with durability, efficiency, and flexibility in mind.

Turnkey Greenhouses – Ready to Use

- Our turnkey greenhouses come pre-designed with essential features, including:

- Durable Accu-Steel framing for long-lasting performance

- Professional-grade fiberglass or polycarbonate panels for optimal light diffusion

- Weather-resistant construction to protect plants year-round

- Multiple sizes and color options to match your outdoor space

Simply choose your size and color, and we’ll deliver a fully assembled, ready-to-use greenhouse for your backyard.

Custom Greenhouses – Built Your Way

Looking for a greenhouse tailored to your exact needs? Our custom greenhouse options allow you to select:

- Size & layout – Small, medium, or large to fit your growing space

- Doors & windows – Insulated doors, vents, and additional windows for airflow

- Shelving & storage – Add shelving, hooks, and benches to maximize organization

Contact Nelson’s Buildings for Your Greenhouse in Gainesville, FL

Nelson’s Buildings offers high-quality, customizable greenhouses designed to meet your gardening needs. Whether you’re looking for a turnkey greenhouse or a custom-built structure with shelving and ventilation, we can help you find the perfect solution. Our durable Accu-Steel greenhouses provide year-round growing opportunities while enhancing your backyard space.

Contact Nelson’s Buildings today in Gainesville by calling (352) 374-7705 or fill out our contact form to get a free quote and learn more about our greenhouse options.

Best Built, Best Price, Best Service.

Top-notch product and customer service.

Daniel arrived promptly on a Friday evening after my garage became inoperable. After replacing two springs and some final tuning I was out the door in 30 minutes.

Ali W.St. Louis, MO